STICKPACK MACHINES

Unified Flex Packaging Technologies is the only manufacturer in North America for Stick Pack Machines!

- Built in Canada & serviced from Appleton, Wisconsin

- Simple and Robust engineering for 24/7 production

- We prebuild inventory up to the point of customization for a head start on manufacturing

- Non-proprietary components to empower our customers for maximum efficiency

MSP800

The MSP800 Multilane VFFS machine is an advanced packaging machine capable of producing high quality stick style packages. Stick packs are shaped like a pillow bag with a top, bottom and back seal. This machine is ideal for medium to high production, depending on the fill volume and flow properties of the product.

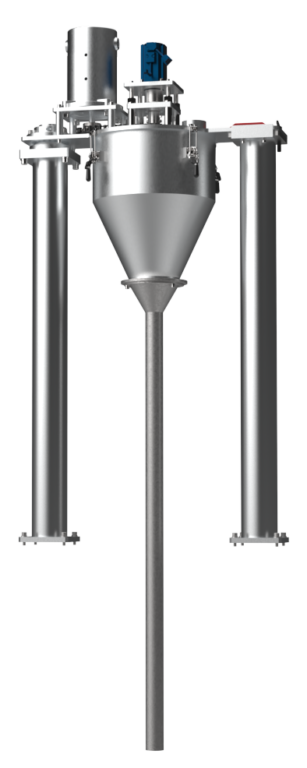

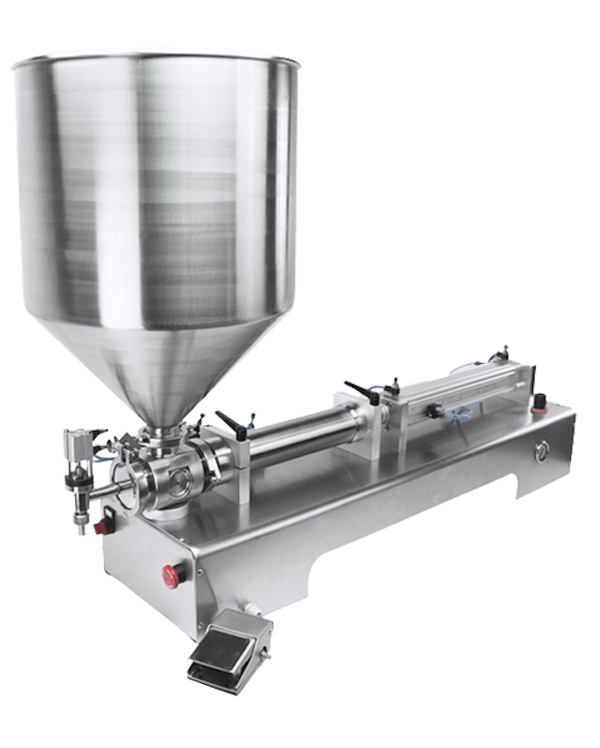

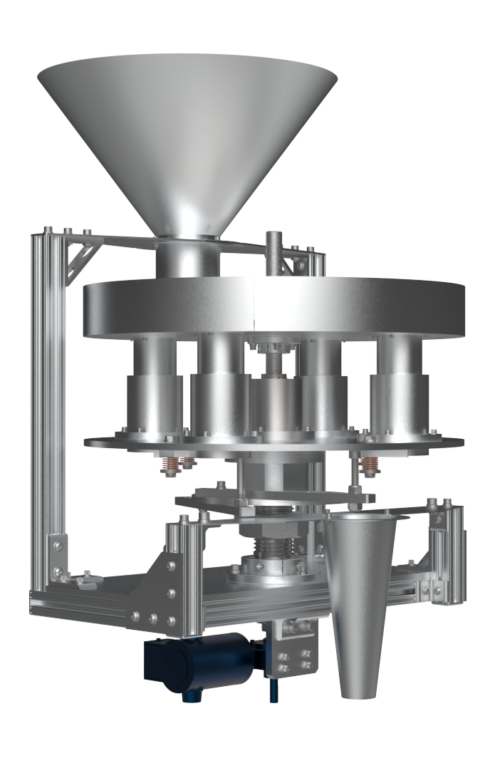

Filler options and brochures provided below :

- Number of lanes: 9 to 14

- Cycles/minute per lane: 40

- Maximum Stick packs/minute: 560

- Maximum web width: 800mm

- Stick pack width: 23mm – 38mm

- Stick pack length: 50mm – 150mm

- Number of lanes: 9 to 14

- Cycles/minute per lane: 40

- Maximum Stick packs/minute: 560

- Maximum web width: 800mm

- Stick pack width: 15mm – 50mm

- Stick pack length: 38mm – 150mm

- Number of lanes: 9 to 21

- Cycles/minute per lane: 40

- Maximum Stick packs/minute: 840

- Maximum web width: 800mm

- Stick pack width: 15mm – 50mm

- Stick pack length: 38mm – 150mm

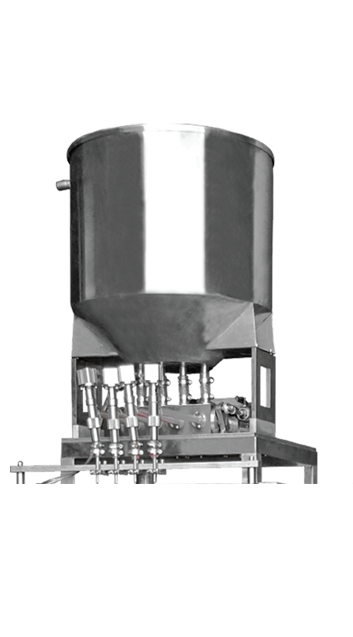

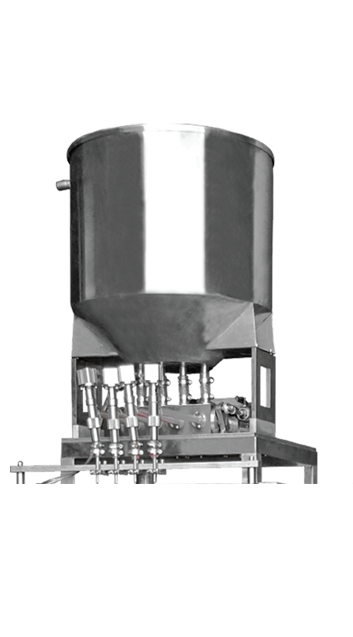

MSP300

The MSP300 Multilane VFFS machine is designed to produce stick packs primarily for single use consumption. It can handle dusty and non-dusty, fine and coarse powders. Up to 7 lanes of stick packs can be packed simultaneously on this machine.MSP300 can package granular products like coffee creamers and similar products.

Filler options and brochures provided below :

- Number of lanes: 3 to 5

- Cycles/minute per lane: 30

- Maximum Stick packs/minute: 150

- Maximum web width: 300mm

- Stick pack width: 23mm – 38mm

- Stick pack length: 50mm – 150mm

- Number of lanes: 3 to 5

- Cycles/minute per lane: 30

- Maximum Stick packs/minute: 150

- Maximum web width: 300mm

- Stick pack width: 23mm – 38mm

- Stick pack length: 50mm – 150mm

- Number of lanes: 3 to 7

- Cycles/minute per lane: 30

- Maximum Stick packs/minute: 210

- Maximum web width: 300mm

- Stick pack width: 15mm – 38mm

- Stick pack length: 50mm – 150mm

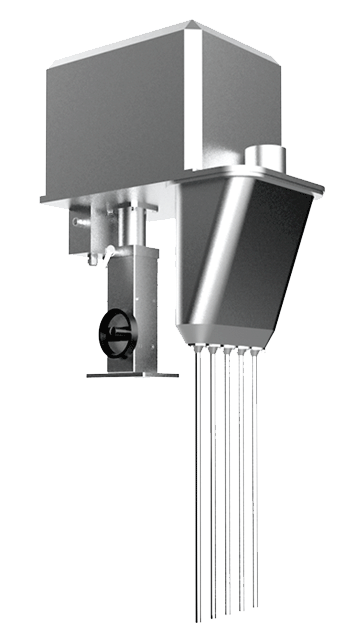

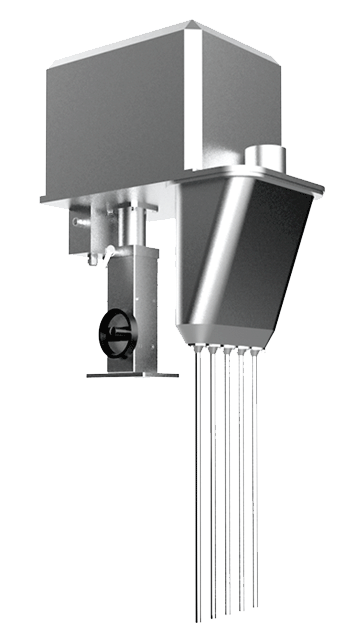

AP140

The AP140 Auto Pouch bagger is designed to be a modular and flexible automatic VFFS machine. It is the only machine in the market that can pack stick packs, pillow packs, pillow packs with gusset, 3 side seal bags and 4 side seal bags with a simple tooling change over. AP-140 can be used to package solid, granular, powders and liquid products.

Filler options and brochures provided below :

- Number of lanes: 1

- Cycles/minute per lane: 30

- Maximum cycles/minute: 30

- Maximum web width: 228mm

- Stick pack width: up to 30mm

- Stick pack length: 228mm

- Number of lanes: 1

- Cycles/minute per lane: 30

- Maximum cycles/minute: 30

- Maximum web width: 228mm

- Stick pack width: up to 30mm

- Stick pack length: 228mm

- Number of lanes: 1

- Cycles/minute per lane: 30

- Maximum cycles/minute: 30

- Maximum web width: 280mm

- Stick pack width: up to 30mm

- Stick pack length: 228mm

ABOUT OUR MANUFACTURING

Tailor Made from the ground up, Unified Flex Systems are built to suit your unique application requirements.

We take great pride in every aspect and detail that goes into each machine we manufacture.

Quality Control and Precision Manufacturing are key for all our systems. Being located in the Waterloo Region of Ontario, we are able to draw on the high tech expertise this Canadian hub offers.

Simple & Robust Engineering

ensures 24/7 production.

Our Canadian and US based service technicians are available for technical support along with an

online portal for documentation.

Motion Control Technology delivers accuracy and consistency. At the same time, we realize the importance of reliability, so we use quality non-proprietary parts for quick service and maximum uptime.

Tailor Made from the ground up, Unified Flex Systems are built to suit your unique application requirements.

We take great pride in every aspect and detail that goes into each machine we manufacture.

Quality Control and Precision Manufacturing are key for all our systems. Being located in the Waterloo Region of Ontario, we are able to draw on the high tech expertise this Canadian hub offers.

Simple & Robust Engineering

ensures 24/7 production.

Our Canadian and US based service technicians are available for technical support along with an

online portal for documentation.

Motion Control Technology delivers accuracy and consistency. At the same time, we realize the importance of reliability, so we use quality non-proprietary parts for quick service and maximum uptime.