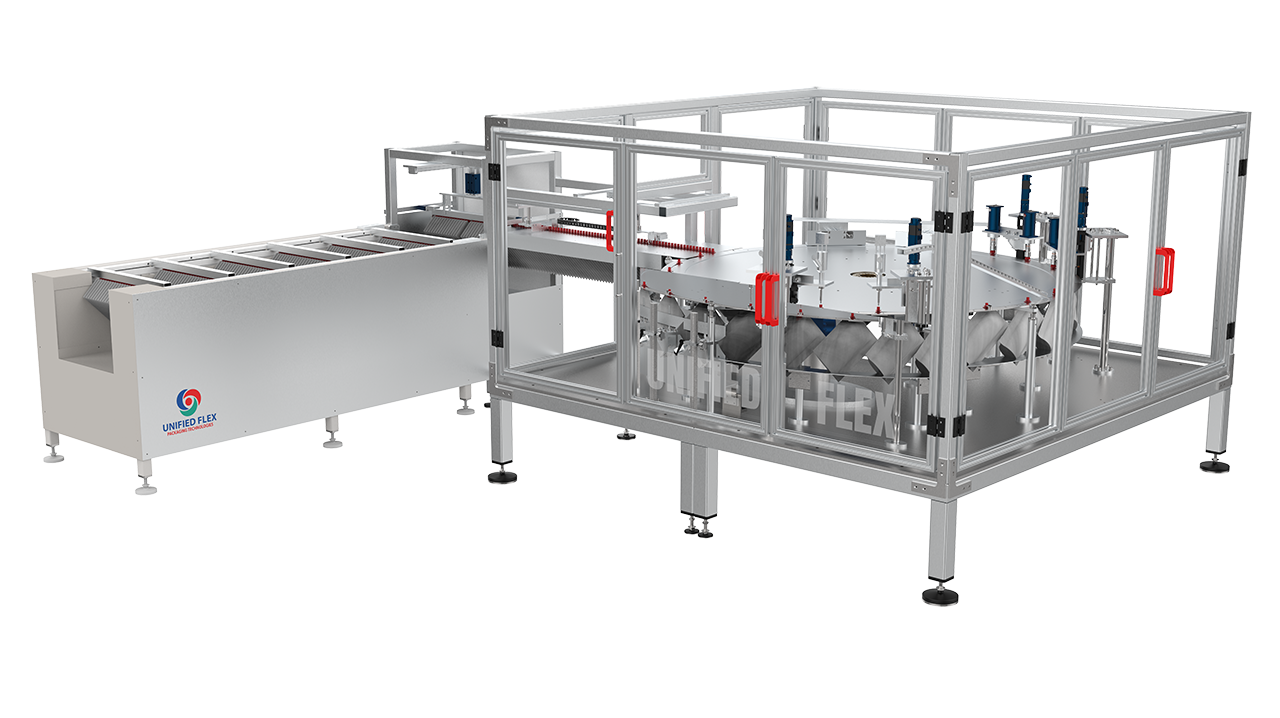

SPOUTED POUCH FILLER AND CAPPER

The best alternative to rigid packaging. Unified Flex provides a cost-effective option for liquid fill applications

- Built in Canada & serviced from Appleton, Wisconsin

- Simple and Robust engineering for 24/7 production

- We prebuild inventory up to the point of customization for a head start on manufacturing

- Non-proprietary components to empower our customers for maximum efficiency

SPOUTED POUCH FILLER AND CAPPER

The Spouted Pouch Filler and Capper can process up to two or four premade pouches at once based on a two or four filler setup. This rotary pouch filling and capping machine can pack viscous and free flowing liquids even those containing particulates. Ideal for various liquid fill applications like edible oils, dressings, sauces, drinks, juices, alternate dairy and more. Non-edible applications include synthetic oils, liquid soaps, paint, shampoo, lotions, liquid detergents and more. Easy integration with piston fillers makes this machine a top choice for complete liquid packaging solutions.

SPEED: UP TO 80 BAGS/MIN. | BAG WIDTH: 8.86″ MAX. | BAG LENGTH: 12.4″ MAX

SPOUTED POUCHES

Unified Flex offers custom printed Spouted Pouches which are ideal for liquids. A Spouted Pouch is essentially a DOY Stand Up Pouch with a capped fitment sealed to the pouch. This pouch is designed as an alternative to rigid packaging made from plastic or glass. It offers excellent surface area for brand messaging and it keeps the brand in front of the customer more effective than a rigid cylindrical container.

At Unified Flex we can help your brand convert from rigid packaging to Spouted Pouch. We offer exceptional Package Development Services to guide you through all aspects of package transformation. Our Spouted Pouch allows for convenient dispensing, almost complete evacuation of product and excellent shelf appeal.

BENEFITS OF USING SPOUTED POUCHES:

- Cost effective flexible compared to rigid packaging.

- Lighter in weight than rigid packaging.

- Excellent shelf appeal.

- Almost complete evacuation of product from the pouch.

- Convenient handling and transportation.

- Eco friendly packaging reduces corporate carbon foot print.

- Requires less space in transportation and distribution.

- Up to 10 color rotogravure Printing.

- Glossy , matte or UV finishing.

- Metalized and non-metalized material structures can be used.

SUITABLE MARKETS:

- Cooking Oils

- Laundry Detergents

- Juices

- Water

- Alcoholic

- Sauces

- Syrups

- Shampoo & Lotions

- Household Chemicals

- Lubricants

ABOUT OUR MANUFACTURING

Tailor Made from the ground up,

Unified Flex Systems are built to suit

your unique application requirements.

We take great pride in every aspect

and detail that goes into each

machine we manufacture.

Quality Control and Precision Manufacturing are key for all our systems. Being located in the Waterloo Region of Ontario, we are able to draw on the high tech expertise this Canadian hub offers.

Simple & Robust Engineering

ensures 24/7 production.

Our Canadian and US based service

technicians are available for

technical support along with an

online portal for documentation.

Motion Control Technology delivers accuracy and consistency. At the same time, we realize the importance of reliability, so we use quality non-proprietary parts for quick service and maximum uptime.