PRINTERS

UNIFIED FLEX HAS 8 PRINTERS TO CUSTOMIZE YOUR SOLUTIONS.

Open a limitless set of possibilities while saving cost and time by printing directly onto flexible packaging. Our printers help businesses reduce their time-to-market, waste & inventory. Unified Flex Packaging Technologies has a complete line of high-performance, cost-effective printers for your product’s needs. From simple date and lot coding to complete roll stock printing, we have a printer that’s right for you.

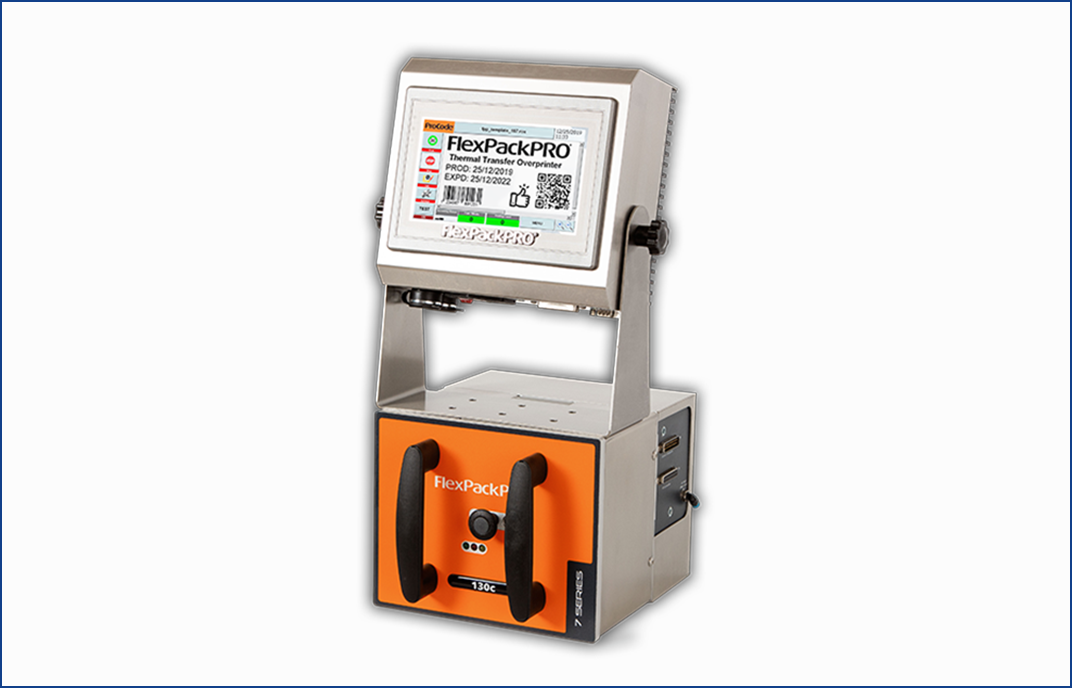

Our FlexPackPRO thermal transfer overprinters (TTO Printers) are perfect for printing variable date codes, barcodes, text and graphics on flexible packaging film, labels, pouches, sheets, card stock and other materials. These thermal transfer overprinters (TTO Printers) integrate easily with new or pre-existing packaging lines and offer unmatched reliability.

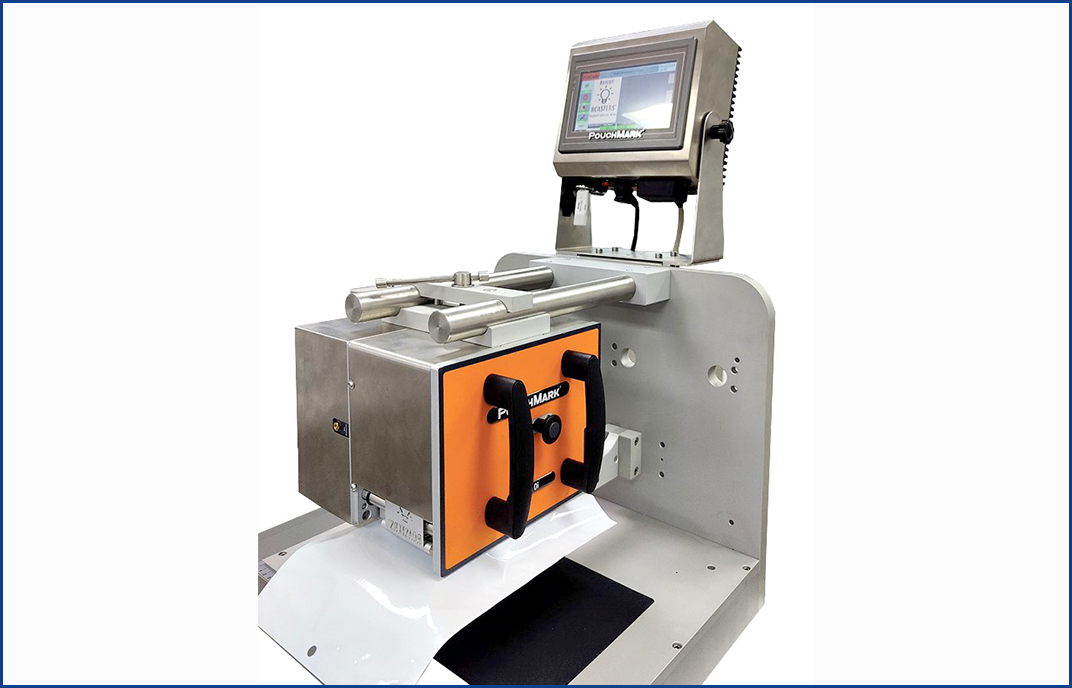

Moreover, our PouchMark® pouch printing solutions offer an all-in-one, turn-key system designed specifically to print variable data directly on to pre-formed pouches, bags, and sachets. These table-top systems feature a range of integrated feeder systems to accommodate nearly any pouch, including gusseted or zipper bags.

Lastly if you’re looking for complete flexibility in your printing solution then our Afinia FP-230 can help you produce flexible packaging on demand. Just design and print laminated rollstock for your VFFS machines whenever you want. FP-230 lets you print and laminate your own high-quality, full-color flexible packaging with ease. Take advantage of these benefits with Unified Flex’s flexible packaging printing solutions and select the right printer for you.

Small, economical, high-performance 32mm TTO printers (1.3”) for traditional date and lot coding on flexible packaging and labels.

Perfect for small packaging machines and

labelers.

Download Brochure

• 32mm (1.3”) wide, 300dpi Printhead

• Continuous & Intermittent Motion

• Perfect for “small footprint” expiration dates & lot codes

• Economical digital upgrade from hot stamp printers and roller coders

• Recommended for packaging machines

Among the most popular TTO printers on the market, FlexPackPRO® 210 Series coders provide high-resolution barcodes, date codes, text and graphics in virtually any packaging and labeling environment.

Download Brochure

• 53mm (2.1”) wide, 300dpi Printhead

• Continuous & Intermittent Motion

• Highest-speed performance for heavy volume applications

• Superior, cost-effective replacement for other brands of 53mm TTO

• Broadest variety of models, from entry level to industrial

For those applications requiring larger format codes, text and graphics, there is no better combination of performance and value than these outstanding 4.2” wide Thermal Transfer Over printers (TTO printers).

Download Brochure

• 107mm (4.2”) wide, 300dpi Printhead

• Continuous & Intermittent Motion

• Print larger combinations of codes, logos, text and graphics

• Excellent option for prtinting variable ingredients and nutrition panels

• Up to 4.2” x 10” print area

Featuring a 5” wide, 300 dpi printhead—the 500 series models are perfect for even larger format applications, offering a print area of up to 5” x 8”!

Download Brochure

• 128mm (5” wide), 300dpi Printhead

• Continuous & Intermittent Motion

• Largest Available TTO Print Area (5” x 8”)

• Fit logos, barcodes, date codes, ingredients, nutrition statements and more in one template

The FLOW 2000™ prints a 7-inch-tall stack of flat pouches (or cards) at a blazing-fast speed of up to 120 packs per minute. And not just simple text or date codes – 1D, 2D and GS1 barcodes; logos and icons incremental and database-fed variable codes…all at crisp and clear 300dpi resolution.

Download Brochure

• Up to 180 packs per min

• Text, Date codes – 1D, 2D and GS1 barcodes

• Prints Logos and Icons as well

•300 dpi resolution

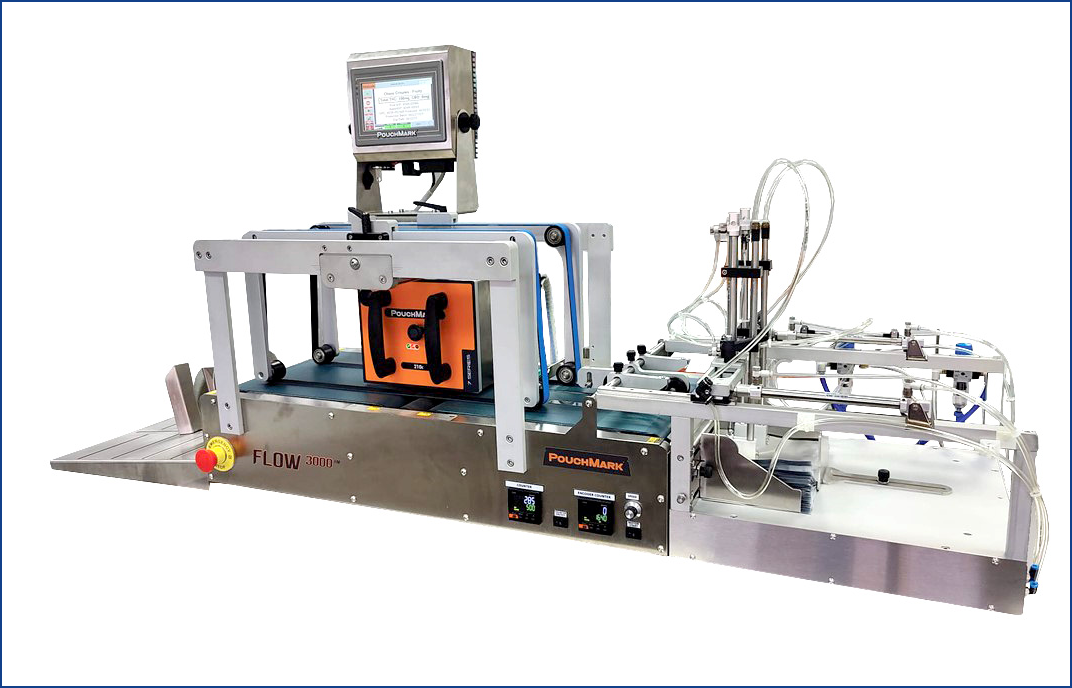

The FLOW 3000™ is the perfect solution for printing variable codes directly onto premade zippered and gusseted pouches. Print everything from nutrition panels, compliance data, logos, virtually any type of barcode and more, eliminating the need for pre-printed, hand or machine-applied labels.

Download Brochure

• Compatible with zippered & gusseted pouches

• Nutrition panels, compliance data, production codes, logos, text & barcode

Custom-print and brand your own bags, pouches and cards on-demand, without going through to the expense and trouble of buying custom-printed labels to apply by hand. Download Brochure

• Touchscreen controller

• User-friendly Windows-based software

• Multi-layered zippered or gusseted bags

The FP-230 has revolutionized packaging roll production. Impressively compact and easy to operate, the FP-230 lets you print and laminate your own high-quality, full-color flexible packaging with ease. Ideal for small to medium runs and high levels of varying data or design. Download Brochure

• Production speed up to 18m/minute

• Exceptional 1600dpi resolution

• EU & FDA food compliant

• Easy variable data

• No minimum order quantities