Custom Printed Rollstock

ROLLSTOCK FILM PRODUCT INFORMATION:

Our custom extruded and laminated films work efficiently with both Vertical form fill and horizontal form fill seal machines. We configure the rollstock film to suit your application and your budget. All our products are available with the following features:

- Up to 10 color rotogravure process

- Glossy finish, matte finish or a combination finish material

- Reverse printing and surface printing capability

- Easy to open Poly structures also available

High Barrier Film Laminations:

- Available in foil or clear laminations

- Ideal where a high barrier is required from oxygen, moisture, and chemicals

- Longer shelf life

- Maximum durability

- Custom poly film extrusions for excellent sealing

- Alox coating, PVDC, HDPE and EVOH custom extrusions available

Metalized Films Laminations:

- Excellent barrier properties

- Excellent bonding properties

- Metalized BOPET films

- Metalized BOPP films

- Metalized Polyester films

OPP Film Laminations:

- BOPP and High Strength BOPP, CPP Films

- Good dimensional strength

- Good Stiffness

- Resistance to tear and abrasion

- Cost-effective

Stickpack Films:

- Easy tear properties

- Excellent barrier to oxygen & moisture

- Good stiffness properties

- Superior sealing characteristics

- Custom formulations for liquid or powder applications

Products:

Flexible packaging films are often referred to as flexible packaging rollstock or flexible packaging laminates. We supply high-quality flexible packaging rollstock specifically configured for optimal performance based on the needs of our customers with food safety and shelf longevity in mind.

Our packaging specialists work with our customers through every stage of packaging development meeting their expectations and maintaining brand integrity.

Through package engineering we determine the size, shape and material composition suitable for desired results. The benefit of being a well-established packaging equipment manufacturer, we can determine packaging material compatibility with the filling equipment.

We have creative in-house graphic designers to assist with all elements of graphic design including prototype and pre-press due diligence.

The Unified Flex Advantage

Our value-added package development services make our Rollstock products top performers in the industry. Our Rollstock products offer the following benefits:

- Consistent friction properties

- Consistent sealing properties

- Consistent barrier protection

- Consistent color printing

- Reduced down time

- Minimal to no wastage of film

- Quick splicing of a new roll of film

- Faster operating speeds

Food Safety:

Every batch of production undergoes the following tests to meet highest food safety standards.

- Solvent residue detection

- Microbial detection

- Peel strength detection

- Seal strength detection

- Pressure & drop properties detection

We only choose partners throughout our supply chain who share the highest standards of food safety in their business practices. Our Rollstock product meets all of the below Global Standard Certifications.

Materials Engineering:

We use highest quality resins manufactured by global leaders such as BASF, Dupont and Dow Chemicals to extrude our flexible packaging films. All flexible packaging films we produce are customized to match the use and application of the film. Shelf life expectancy is carefully measured by calculating the rate of flow for oxygen and water vapour through the packaging materials. We offer a wide variety of metalized and non-metalized flexible packaging films which can be configured in various compositions to formulate the appropriate packaging material for the application. Our chemical engineers bring decades of formulation experience for food packaging applications maintaining the aroma, taste and physical properties of the food products. We also specialize in co-extruded LLDPE & HDPE films. Co-extruded films can be used as stand-alone films or in laminated structures to provide excellent sealing properties to the package.

Color Management:

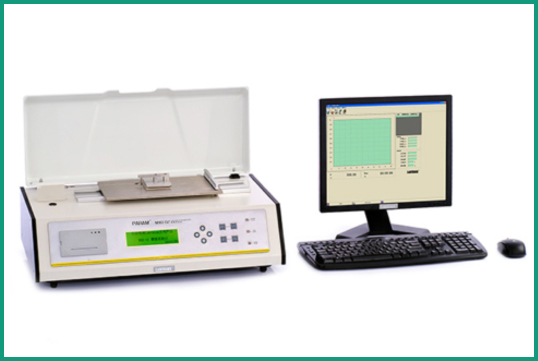

Achieving desired colors on flexible packaging products is imperative for great shelf appeal. A properly printed package attracts attention of the eye and results in more sales for the product. Our flexible packaging printing equipment uses inline high-resolution spectrophotometers to measure and monitor the color data. This system helps us generate exact colors required for printing. It can quantify colors equally well on high gloss surfaces as well as metalized shiny surfaces. This results in efficiently matching the printed colors closest to the specified colors on the computer-generated artwork. This process also makes our manufacturing process more efficient and reliable and helps in reducing cost for the printed products. An offline high-speed inspection machine also checks the quality of the printed film and splices out any inconsistencies in printing quality.

Quality Control:

Our goal is to achieve 100% customer satisfaction by providing reliable, consistent & high quality flexible packaging products. We have developed strict quality control mechanisms that measure all aspects of flexible packaging products from receiving of raw materials in our manufacturing facility to the final packaging and shipping of good.

COF Detection

On high speed film converting and printing machines the static friction coefficient of the film is a major factor in determining the performance characteristics of the film during production. COF is also important to monitor and maintain as the flow properties of flexible packaging materials change with a change in COF, potentially causing disruptions on packaging equipment. Unified flex evaluates friction coefficient according to ASTM D1894 standards.

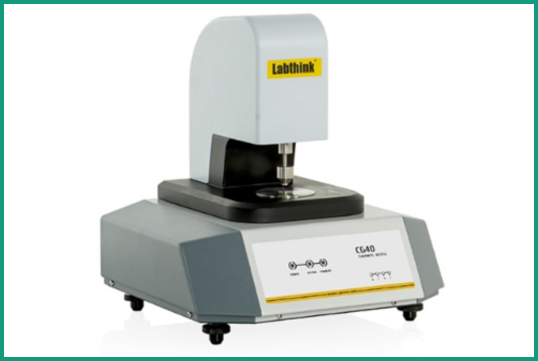

Thickness Detection

The thickness of flexible packaging films determines the clarity, durability and flexibility of the films. As thickness increases, clarity and flexibility reduces while the durability of the film increases. Pre and post production tests are performed using a mechanical micrometer. Flexible packaging films with consistent thickness do not overstrain and stretch during the printing process resulting in superior print quality.

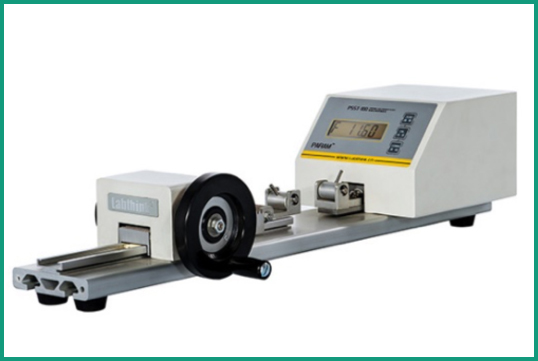

Sealing Test

Heat seal is the most popular method of welding plastics materials. One of the most important characteristics of flexible packaging materials is the sealing properties of the film. All films are tested under specific temperature, dwell time and pneumatic pressure. Sealing strengths of the flexible packaging films are measured according to the ASTM 882 standards.

Tensile Strength

Tensile strength is the maximum mechanical stress a packaging material can withstand without breaking. We test our films for tensile strength as its an important property of the flexible packaging material. This test can determine the peel force, tear force, elongation rate , puncture resistance and adhesive strengths of the films. Unified flex ensures compliance with requirements on strength characteristics in accordance with ASTM 882 standards.