OUR Story

Beginnings:

Unified’s story is not about decades of experience, global presence or hundreds of employees, instead our story is about entrepreneurship, passion, and a strong determination to succeed. Our journey started in 2002 when Al started working for a used VFFS equipment dealer as a Sales Rep. Quickly, he realized customers were not happy as the machines would break down often and the parts were expensive to replace. OEM manufacturers would sell proprietary parts at a high margin and sometimes would take for ever to deliver. In a few years Al learned to troubleshoot and fix the machines himself to get the customers back in production quickly. Replacing the parts sometimes was quite time consuming and Al would wonder why a company would position a critical component in a difficult spot that requires an entire sub assembly to come apart for replacing a wear and tear component. Later on, he realized that most OEM manufacturer’s drive 20% -30% of their revenue from parts and service sales and hence it all it made sense.

Opportunity:

Al realized a gap existed in the market for an OEM manufacturer who builds VFFS machines utilizing a simple yet robust design with off the shelf parts at a reasonable price. After troubleshooting and repairing VFFS machines for a few years Al knew exactly what not to do. For the next few months, he spent a lot of time on designing his First VFFS machine. With the help of family and friends, funds were raised to manufacture the dream machine. Al rented a small space at his friend’s machine shop; a panel shop was hired to design and build the controls and a programmer friend provided services to be paid after the machine was sold. Few months later at the 11 hour of the night the machine produced its first bag. The bag was not perfect, but it was a moment of success and happiness. Machine was further refined and tested for quality. Machine was named VertoBagger as in Vertical Bagger. Al partnered with a friend in Buffalo NY and launched American Packaging & Plant Equipment (APPE) in 2007.

Questions:

Al and his partner thought the machine and the company would be an instant success once they start calling on customers. Little that they knew that the brand behind the machine was more important than the machine itself. Customers would ask how many of these machines have you sold so far? Where can I see a machine running in a plant? Where would I get help if you are out of business tomorrow? How would I know this machine would be reliable few years from now? Al and his partner didn’t have convincing answers to all the valid questions customers would have. The first year went by without any revenue. Al’s Partner jumped off the boat after the first year and Al moved the business to Canada. He continued to call on customers and he faced one rejection after another. His passion for equipment kept increasing as he unsuccessfully tried convincing customers to buy the equipment. He was running out of time as debt kept piling and the company was down to the last few hundred dollars with no more financial resources to count on.

Chance:

Next day Al received a call from a customer who rejected to buy the machine few months ago. Customer inquired if Al still had the machine and would ship him urgently. He would pay cash upon delivery as he needed to start packaging immediately for a big customer. He would not care about the brand as long as the machine worked and got the job done. That was the chance Al needed and the company was born that day. Al realized if he was to pursue his passion for VFFS machines it would take decades to build a brand and the journey won’t be easy. Leaving a lucrative career in sales behind Al decided to pursue his passion and kept selling and building VFFS machines at low prices for local customers. After a handful of successful installations Al knew he could grow the list of happy customers and sell successfully to a certain clientele at a certain price.

Brand:

Al spent a lot of time in the field installing machines, training operators and maintenance staff. Few months after every successful install he would ask customer staff to provide feedback on what they like or dislike about the machine. Valid recommendations were incorporated to the design. He would ask the management reasons behind their decision to purchase the VertoBagger. Al got the same response from most customers, that they bought the VertoBagger because they evaluated it to be simple and robust with competitive pricing. Customers acknowledged The VertoBagger machines were performing better than the big brand OEM machines due to precision fit and form of the machine compared to competition. Customers felt empowered that they could buy off the shelf parts at reasonable prices from the vendor of their choice. Hence foundations of a future global brand of VFFS machines were laid on the principles of simple designs, robust mechanisms, competitive pricing, precision manufacturing and empowering the customers.

Technology:

Our VFFS machines are built using best in class electro-mechanical components. #304 Stainless Steel laser welded frames. CNC manufactured high precision parts made from anodized aluminum or #304 Stainless are used as building blocks of the machine. Industry 4.0 ready Allen Bradley or Omron motion controllers are used for round the clock operation of the machines. McMaster Carr high precision linear and radial bearing used for mechanical motion. SICK contrast sensors are used for print mark registration. Precision heat seal tooling with pulsing temperature controllers. Over 100 accessories and attachments available for VFFS machines. 15 unique models providing endless possibilities of customization for bag style and features. Solutions available from entry level machines to high-speed continuous motion machines. Every machine is tailor made to meet customer requirements. Ultrasonic and Impulse sealing technologies are available for sustainable packaging solutions.

Investors:

Company was rebranded as Unified Flex Packaging Technologies in 2018 as investment partners came on board. New product lines of packaging film rollstock and stand-up pouches were added as consumables. R&D in sustainable solutions was undertaken for developing new VFFS technologies to meet future demand. Core brand values were maintained with respect to equipment design approach. Corporate management and structured growth plan introduced to achieve new milestones. Unified Flex’s approach is to develop long term partnerships with its customers by providing high quality state of the art turnkey packaging equipment. Customize the equipment to meet unique application needs. And support customers with high quality films and pouches. We hope to transition our customers in sustainable consumable products in near future.

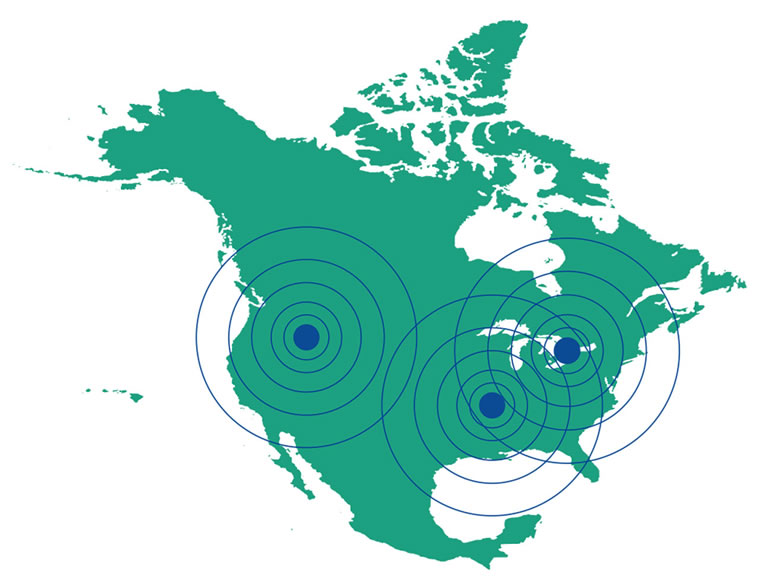

OUR Locations

Unified Flex operates multiple sales and service centers with a centralized manufacturing facility. This wide spread presence allows us to serve our customers across North America quickly and efficiently.

CORPORATE OFFICE:

510 Thompson Drive, Unit 12 Cambridge, ON N1T 2K8, Canada.

CANADIAN REGIONAL OFFICE:

4170 Still Creek Drive, Suite 200, Burnaby, British Columbia, V5C 6C6, Canada.

US REGIONAL OFFICE:

923 Haddonfield Rd. Suite 300, Cherry Hill, New Jersey, 08002, U.S.A.

woodstock Plant:

465 Griffin Way Woodstock Ontario N4T 0N2.

Contact:

Phone: 1-866-369-4181

Fax: 1-416-352-1366

Email: leads@unifiedflex.com