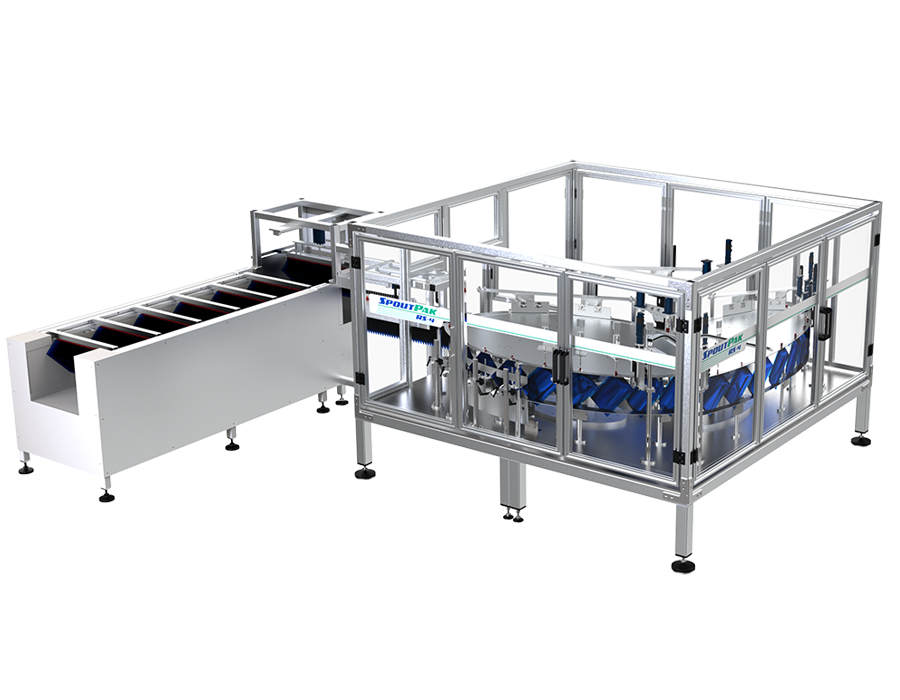

SPOUTPACK RS-4

UNIFED FLEX PRESENTS SPOUTPACK RS-4

SPOUTPACK RS-4 can processes up to two or four premade pouches at once based on a two or four filler setup. This rotary pouch filling & capping machine can pack viscous & free flowing liquids even those containing particulates. Ideal for various liquid fill applications like edible oils, dressings, sauces, drinks, juices, alternate dairy and more. Non-edible applications include synthetic oils, liquid soaps, paint, shampoo, lotions, liquid detergents and more. Easy integration with piston fillers makes this machine a top choice for complete liquid packaging solutions.

Bag style possibilities with this machine. Click on a desired bag style to learn more.

Spouted Pouch

- Ability to pack Spouted Pouches

- Packs up to 8.86” wide (225mm) x 12.4” long (315mm) pouches

- Packs up to 80 pouches per minute

- 4 up tooling with 15-20 cycles /min

- Possible speeds of up 80 pouches /min

- Easy tooling change over for various sizes of pouches

- Heavy duty rotary indexer for precise placement of pouches on every cycle

- Easy pouch magazine load on indexing conveyor

- Automatic pick and placement of pouches in the rotary table

- Set of 4 ink jet print heads for best before date printing

- Automatic discard of empty pouch magazine

- Pouch detection capability. No pouch – No fill capability

- Set of 4 filling piston pumps with easy volume adjustment

- Set of 2 servo-controlled filling stations built with single axis robots

- Variable frequency bowl feeder with ramp with vibratory reservoir hopper

- Ramp with spring clamps with auto cap placement on pouches

- Set of 2 servo-controlled filling stations built with single axis robots

- Set of 4 independent capping heads with torque out capability

- Stainless Steel Eject chutes for easy pouch collection

- Stainless-Steel over-all construction with continuous welds

- Omron motion controller for synchronous and smooth motion

- 10” enclosed HMI with easy menus for various operations

- Off the shelf nonproprietary parts

| Standard technical data | Rotary Pouch Fill & Cap Machine |

| Machine height | 72” |

| Machine width | 180” |

| Machine length | 120” |

| Controls | Motion Controller |

| Electrical power supply | 220-volt , Single Phase , 30 Amps |

| Human machine interface | Color Touch Screen |

| Air pressure | 90 psi |

| Power consumption | 3 kw |

| Fill Range | 100 ml to 2000 ml |

| Pouch Width Range | 3.15 Inches (80mm) - 8.86 Inches (225mm) |

| Pouch Length | 5.12 Inches (130mm) – 12.4 Inches (315mm) |

- Take away conveyor

- Free flowing piston fillers

- Viscous Piston filler

- Gas flush

At Unified Flex we believe in empowering our customers. We use non-proprietary off the shelf parts on all our machines. Click on the link below to find out more.

At Unified Flex we believe service is equally important as manufacturing high-quality equipment. We offer a wide variety of pre-delivery and post-delivery services. Click on the link below to find out more.

WHAT MAKES US BETTER THAN OUR COMPETITORS?

✓ Simple, Robust & Precise machines

✓ Off the shelf non proprietary parts

✓ Turn-Key solutions

✓ Tailored to fit your application

✓ Manufactured in Canada

✓ Installation & On going support

✓ Automated bagger Specialists

✓ Bagger experience & specialists

✓ Quick return on the investment

✓ Packaging film solution

TESTIMONIAL

We’ve been working with Al Aman and his team at Unified Flex for approximately 5 years. Unified Flex worked on all aspects of our needs to make our process better. They were willing to do what we needed to get done and delivered exactly what we wanted. Not only did Unified Flex provide us with the most economical options, they also provided an exceptional service level that we couldn’t have asked for any better. The best part was, that we got the best bang-for-our-buck. We know we could have spent many times more than what we did. I count it a privilege to be working with Unified Flex on this project. Gleanings needs you! I need a partner who understands packaging machinery and can work with me by putting our combined knowledge together and come up with the best machine for Gleanings. Our application was unique and challenging because it required equipment that could produce a special shaped pouch. Filling the pouches also produced challenges because of the viscosity of our product. In June 2016 Unified Flex provided us with a customized turnkey system and high-quality packaging film that fit our application perfectly. They also provided us with training and technical support to overcome each challenge that surfaced. We are impressed with the high-quality packaging film and the exceptional printing quality for our pouches that Unified Flex supply us. All-in-all a total solution that assists us in bringing a unique single serving size product to the market.